Environmental Protection

Protecting the environment is our steadfast responsibility.

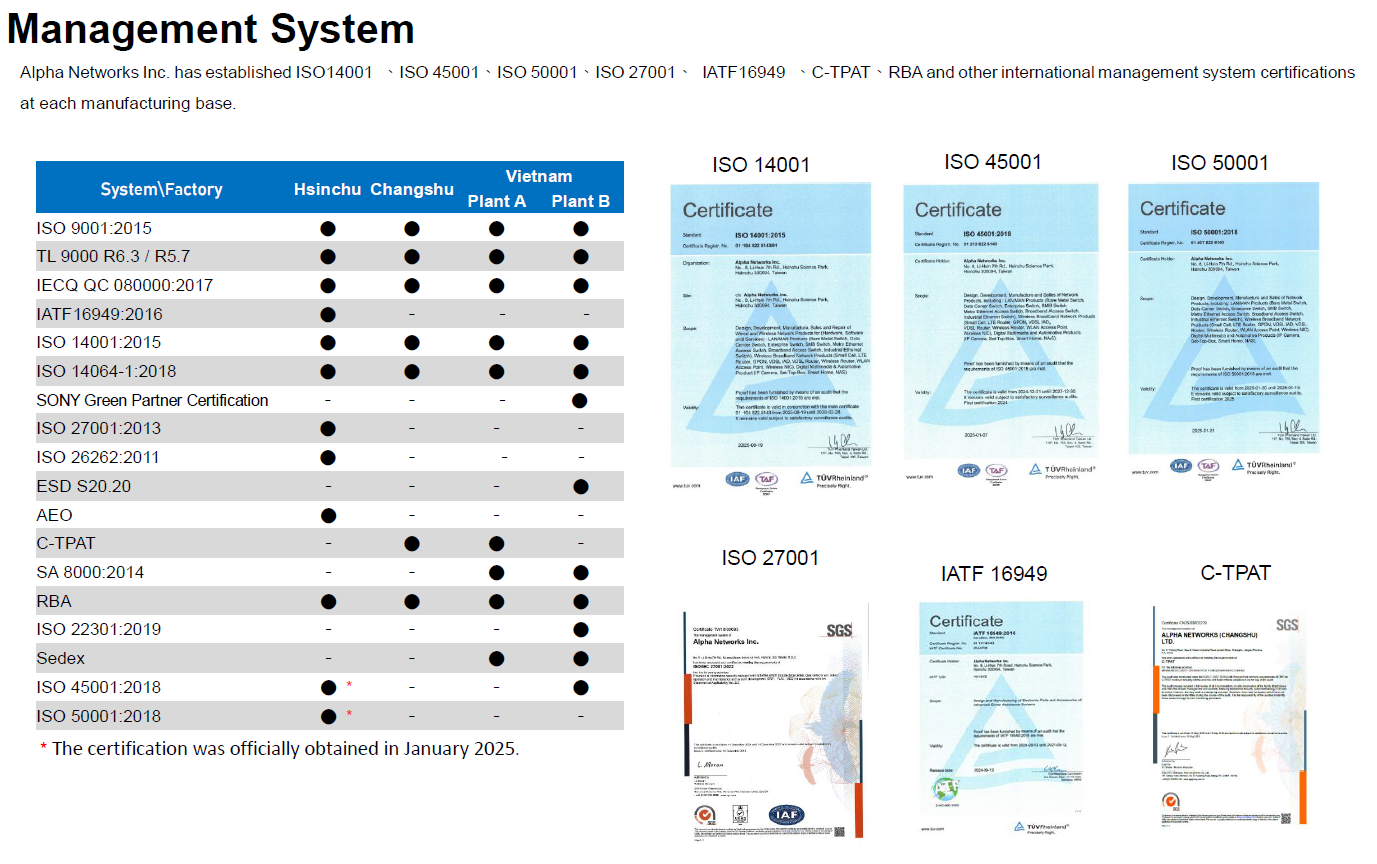

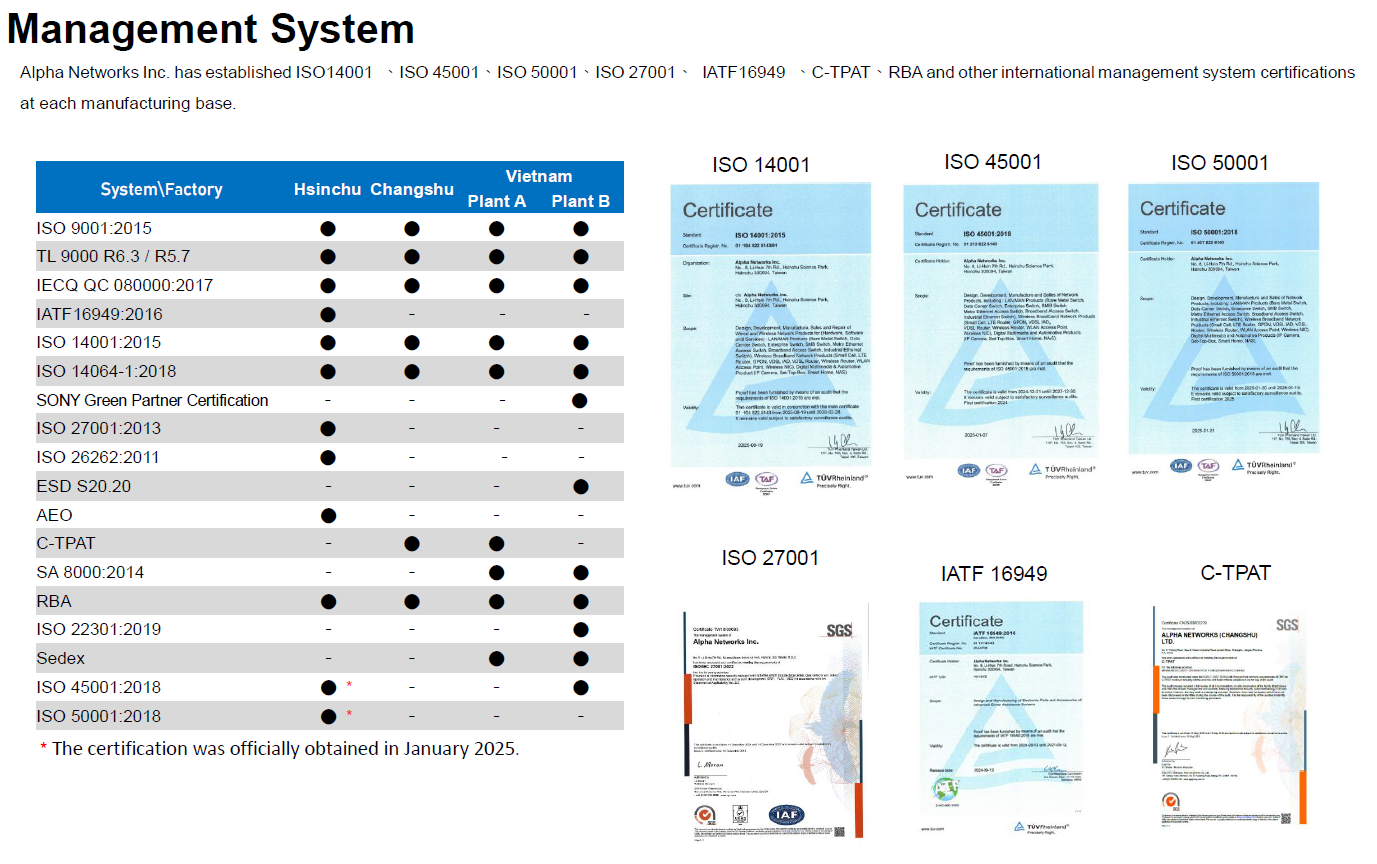

Know more certificate information:ISO 14001、ISO 45001、ISO 50001、ISO 27001、IATF 16949、C-TPAT

Know more certificate information:ISO 14001、ISO 45001、ISO 50001、ISO 27001、IATF 16949、C-TPAT